| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Lingyao

Model Number : LYAPL1-20-I

Certification : CE, ISO, GMP

Place of Origin : China

MOQ : 1 unit

Price : USD 150,000-350,000 per unit

Payment Terms : D/A,D/P,T/T,Western Union,MoneyGram

Supply Ability : 1 unit per month

Delivery Time : 180 work days

Packaging Details : carton, wood carton, pallets

Machine Name : Ampoule Filling and Sealing Line

Function : Ampoules Washing, Sterilization, Filling, Sealing

Filling Volume : 1-2ml

Output Capacity : 16000-22000 BPH

Material Compatibility : SS316

Filling Liquid Type : Hyaluronic Acid Injections

Ampoules Material : Glass

Filling Accuracy : +/-0.5%

Breakage Rate : <0.5%

Data Integrity & Traceability : 21 CFR Part 11

Filling Protection Air : Nitrogen

CIP/SIP System : Available

Oven Cooling Style : Water Cooling

Sealing Style : Wire Sealing

LAF System : ISO Class A

After-sales Service & Technical Support : 1-2 years guarantee maintenance, free spare parts available, and troubleshooting assistance to minimize downtime

Automated Ampoule Filling and Sealing Line for Hyaluronic Acid Injection High Filling Speed 22,000BPH, ISO 14644 Compliance

Revolutionize Sterile Injectable Production with Our Automated Ampoule Filling and Sealing Line

Ideal for vaccines, insulin, and biologics, this automated ampoule filling and sealing line combines precision engineering with unmatched sterility. Engineered for high-speed production of 5000 vials/hour, it ensures ±0.5% dosing accuracy through servo-driven pumps—perfect for costly APIs like monoclonal antibodies.

Key Innovations:

Automated Ampoule Filling and Sealing Line Spec:

| technical parameters | ||||

| product model | LYQCL100+LYASMR 620/43+LYAGF8 | |||

| size range | 1-20ml national standard ampoules | |||

| Output(1-2ml) | 16000-22000pcs/h | |||

| Output(5-10ml) | 8000-12000pcs/h | |||

| Output(20ml) | 5000-7000pcs/h | |||

| Clarity | >99% | |||

| Breakage rate | ≤1%(whole line) | |||

| Filling Precision | ±0.5-2%(according to pharmacopoeia standard) | |||

| Water Consumption and Pressure | 0.2-0.4Mpa / 0.6-1.0m³/h | |||

| Cleaning CA Consumption and Pressure | 0.3-0.6Mpa / 35-80m³/h 0.3-1.0Mpa / 35-80m³/h | |||

| Sealed gas | Gas(liquefied gas)+oxygen, oxyhydrogen generation gas, natural gas | |||

| Oxygen consumption | 0.2-0.3Mpa,1.2-1.5m³/h | |||

| Gas consumption | 0.1-0.3Mpa,1.5-2.5m³/h | |||

| Exhaust volume | 3500-4100m³/h | |||

| Net weight | 7800(kg) | |||

| Total power | around 72kw 380V 50HZ | |||

| Outline size | around 9940x2260x2445mm | |||

Operational Excellence:

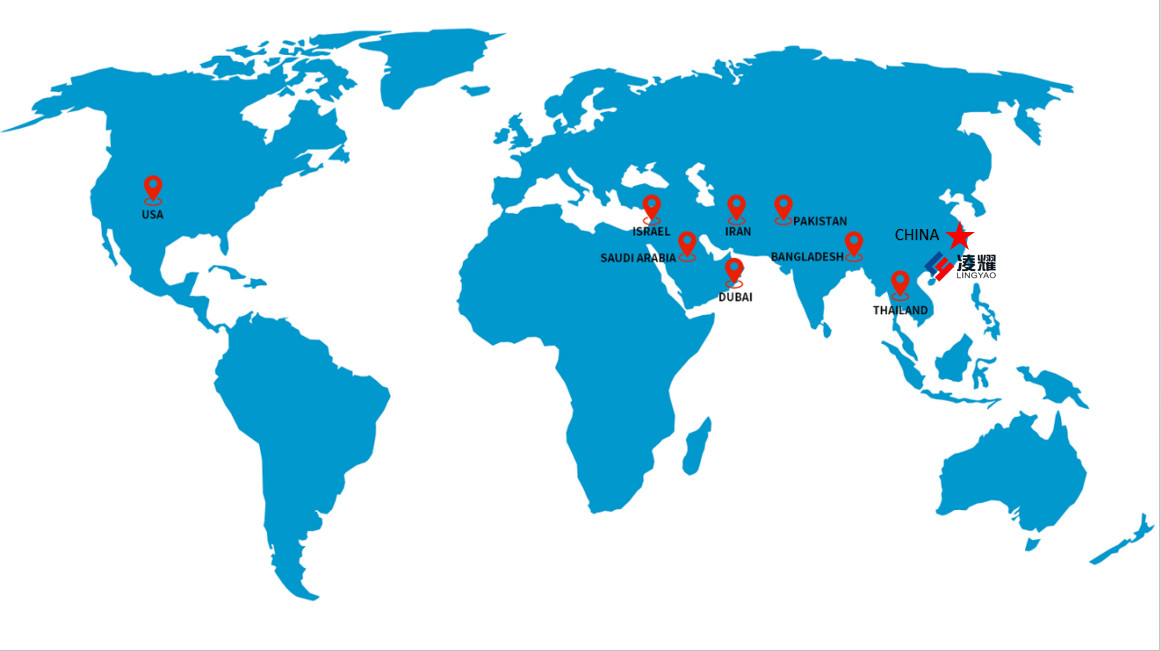

Trusted by pharmaceutical giants in Dubai and Riyadh, this ampoule filling line delivers 20% faster ROI through reduced downtime and 99.9% batch success rates. Request a live demo to experience its game-changing performance!

We are qualified to provide the following services:

Accompanying production services. is acharacteristic service that Lingyao can provide to support our clients:

|

|

Automated Ampoule Filling and Sealing Line for Hyaluronic Acid Injection High Filling Speed 22,000BPH, ISO 14644 Compliance Images |